Analysis of the Technological Evolution and Industrial Value of Particle Packaging Machines

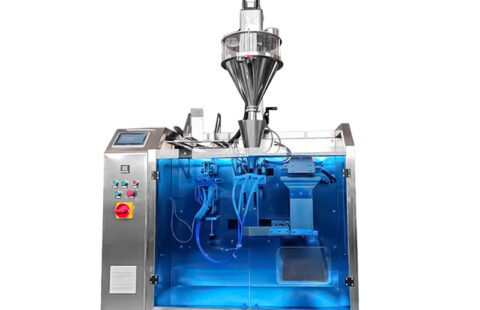

In modern industry, granule packaging machines remain indispensable as core material-packaging equipment. Their efficiency and precision support diverse sectors, from food and pharmaceuticals to chemicals and agriculture. Driven by automation and intelligent technology, these machines are evolving from mechanical control to digital intelligence, marking a transformative leap in production systems.

1.Technical Analysis of Particle Packaging Machine

2.Analysis of Technological Innovation Path

Granule packaging machines now adopt modular designs with standardized interfaces, enabling rapid replacement of measuring/transmission modules to handle particles, powders, and other materials. Replacing pneumatic components with servo motors—combined with fuzzy control for heat-sealing temperature—reduces energy use while maintaining seal quality.

3.The Deep Logic of Industrial Development

Market demands drive rapid innovation: Food industry needs for nitrogen-preservation packaging have spurred multi-gas mixing systems, while pharmaceutical GMP standards push sterile-environment enhancements. This technology-market synergy is reshaping the industry. In 2022, the global intelligent granule packaging market hit $4.7 billion (8.3% CAGR), with modular equipment claiming 35% share.

4.Future technological evolution direction

As industrial IoT matures, granule packaging machines are evolving into networked clusters. 5G-enabled remote systems allow real-time diagnostics for global factories, while blockchain ensures full supply-chain traceability. Meanwhile, MEMS breakthroughs enable millimeter-precision nanoparticle packaging, advancing new material development.

In the context of manufacturing transformation, granule packaging machines have evolved beyond equipment upgrades to become a benchmark for industrial automation. Their development underscores the necessity of integrating precision engineering, intelligent algorithms, and industry-specific demands to drive industrial value. As interdisciplinary technologies converge, these machines will achieve breakthroughs in precision, efficiency, and flexibility, fueling innovation in modern industrial systems.