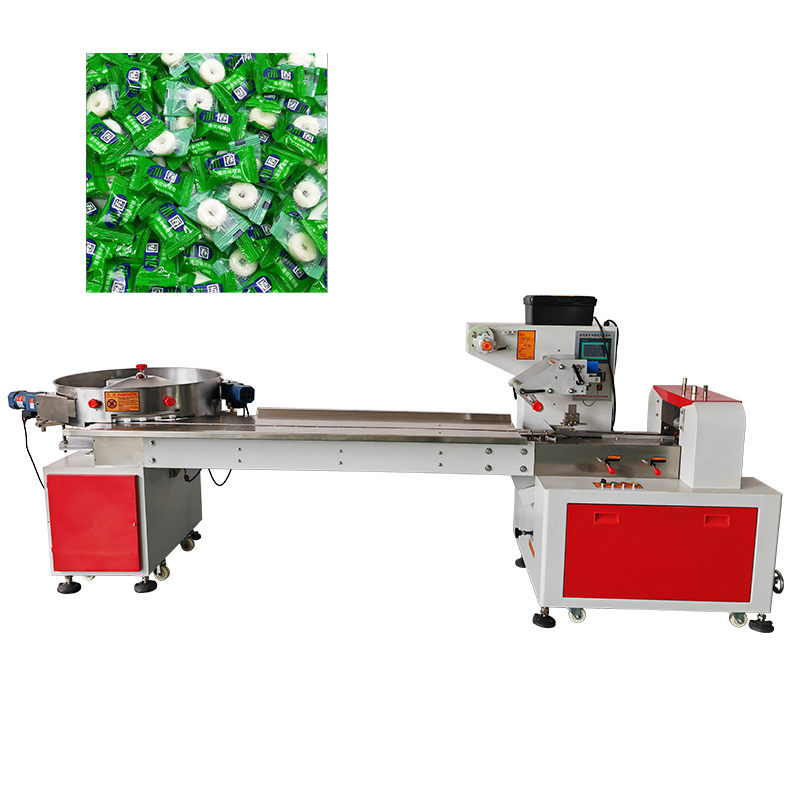

Mint candy packaging machine

The mint candy packaging machine is not only the crystallization of mechanical engineering, but also the carrier of food technology and sustainable development concepts. From the stainless steel casing with cold light flow to the precise cutting of 12 sugar granules per second, this machine redefines the industrial expression of “coolness” with technology – making every mint candy a perfect balance between quality, efficiency, and environmental protection.

Description

I. Appearance Design: Fusion of Industrial Aesthetics and Pragmatism

The peppermint candy wrapping machine features a silver-gray and ice-blue color scheme. Its body is crafted using food-grade 304 stainless steel through a seamless molding process, with a brushed surface that combines corrosion resistance and modern industrial texture. The machine adopts a modular assembly structure:

- Top Section: A transparent acrylic protective cover with an integrated LED cold-light illumination system allows real-time observation of candy movement.

- Mid-Section: Equipped with a 10-inch smart touchscreen interface designed with peppermint leaf vein patterns, supporting multilingual switching.

- Base: A suspended shock-absorbing base paired with honeycomb-shaped heat dissipation grilles ensures quiet operation below 65 decibels.

The side panels incorporate dynamic LED indicator strips that use blue-green gradient lighting to visually display operational status (standby/operational/fault), achieving “visual human-machine interaction.”

II. Working Principles and Process: Precision Engineering for Freshness Preservation

The machine operates via a fully automated assembly line, with four core stages:

- Candy Feeding & Positioning: A vibration feeder aligns peppermint candies, while a 3D vision system (±0.05 mm accuracy) detects candy orientation, and robotic arms adjust them to standardized angles.

- Defect Screening: A near-infrared spectrometer (900-1700 nm wavelength) scans internal structures to identify cracks, hollows, and other defects, achieving a 99.97% rejection rate.

- Low-Temperature Sealing: Dual aluminum foil composite film pre-chilled to -18°C undergoes instant heat sealing under nitrogen-protected blades (65±2°C), reducing menthol evaporation to ≤0.5%.

- Portion Packaging: Wrapped candies enter a rotary measuring hopper for automatic portioning (5-100 pieces/bag), with laser-printed batch numbers applied.

III. Core Advantages: Dual Breakthroughs in Efficiency and Quality

| Aspect | Conventional Machines | This Machine’s Innovations |

|---|---|---|

| Speed | 120-150 pieces/minute | 400-500 pieces/minute (3x faster) |

| Accuracy | Manual sampling miss rate ≥3% | AI vision full inspection, defect rate ≤0.003% |

| Freshness | Menthol loss rate 8-12% | Low-temp sealing, loss rate ≤0.5% |

| Eco-Friendliness | PVC film (100-year degradation) | Corn starch-based film (60-day degradation) |

IV. Application Scenarios: Revolutionizing Freshness from Factories to Daily Life

-

Industrial Food Production

- Compatible with cube, tablet, and irregular-shaped candies, enabling continuous output of 24,000 pieces/hour to meet mass production demands for brands like Wrigley and Mentos.

-

Pharmaceutical Packaging

- Used for menthol-containing throat lozenges, with a cleanroom version meeting GMP standards (microbial count ≤10 CFU/g).

-

Premium Gift Markets

- Integrated UV digital printing module enables customized wrapper designs within 72 hours, ideal for wedding favors and corporate-branded candies.

-

Eco-Demonstration Projects

- Paired with biodegradable materials, achieves a “packaging-transportation-recycling”闭环 in zero-carbon factories, reducing plastic pollution by 32%.