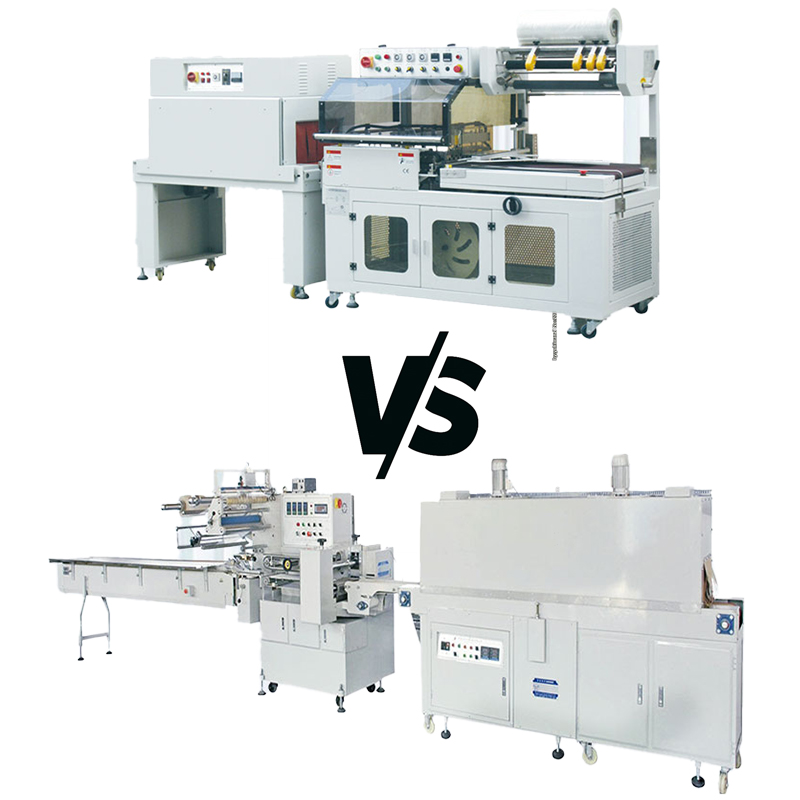

Analysis of Differences Between Pillow-Type and L-Type Shrink Wrapping Machines

In the industrial packaging sector, shrink wrapping machines are widely used for their efficiency, aesthetic appeal, and adaptability. Among them, pillow-type shrink wrapping machines and L-type shrink wrapping machines are two mainstream models, but they differ significantly in structure, functionality, and application scenarios. This article provides a multidimensional comparison to guide enterprises in selecting the appropriate equipment.

1. Structural and Operational Comparison

1. Pillow-Type Shrink Wrapping Machine

- Structure:

Features horizontal conveying and transverse sealing/cutting mechanisms. The film fully encloses the product, forming a “pillow-like” sealed package. Key components include film feeding systems, transverse sealing blades, and heat shrink tunnels. - Operation:

Products enter the packaging zone via a conveyor belt. The film wraps the product vertically, and transverse sealing blades create individual sealed units. These units then pass through a heat tunnel for shrinkage and shaping. - Key Advantages:

High sealing integrity and smooth appearance, ideal for moisture- and dust-sensitive products.

2. L-Type Shrink Wrapping Machine

- Structure:

Utilizes an L-shaped sealing/cutting layout, combining transverse and longitudinal sealing. Often includes a pallet or bottom film support system for semi-enclosed packaging with optional open bases. - Operation:

Products are placed on pallets or bottom film. The L-shaped sealing blade seals the top and sides, followed by longitudinal sealing (or leaving the base open). The package is then heat-shrunk for stability. - Key Advantages:

Enhanced stability for stacking and transport, suitable for multi-item bundles or bulky goods.

2. Core Functional Differences

| Criteria | Pillow-Type Machine | L-Type Machine |

|---|---|---|

| Packaging Design | Fully sealed, no openings | Semi-sealed, open base or pallet-compatible |

| Product Compatibility | Single, regular-shaped items (e.g., snacks, bottles) | Multi-item bundles, irregular/large items (e.g., cartons, machinery) |

| Speed | High-speed (up to 200 packs/min), suited for mass production | Moderate speed (50–100 packs/min), adaptable to variable sizes |

| Material & Cost | Custom-width film; higher initial cost but efficient material use | Universal film or reusable pallets; lower overall costs |

| Automation | Requires automated feeding for unmanned operation | Integrates film wrapping and palletizing modules |

| Space Requirements | Compact footprint for small production lines | Longer heat tunnels demand larger floor space |

3. Typical Applications

Pillow-Type Machines

- Food Industry:

Oxygen- and moisture-proof packaging for single items (e.g., frozen dumplings, instant noodles). - Consumer Goods:

Hygienic packaging for soap, toothpaste, and cosmetics. - Healthcare:

Sterile sealing for medical devices and pharmaceutical bottles.

L-Type Machines

- Logistics:

Pallet stabilization for cartons (e.g., beverages, books) during transit. - E-commerce:

Bundled promotional sets (e.g., gift boxes, holiday baskets). - Industrial Use:

Protective packaging for large machinery parts with palletized bases for forklift handling.

4. Selection Guidelines: Matching Business Needs

-

Choose Pillow-Type Machines When:

- Products are small, uniform, and require full sealing.

- High-speed, high-volume output is critical (e.g., food processing).

- Premium aesthetics are prioritized (e.g., luxury goods).

-

Choose L-Type Machines When:

- Packaging involves palletized or multi-item bundles.

- Frequent size adjustments are needed (e.g., e-commerce warehouses).

- Budget constraints favor reusable materials or lower film costs.

5. Future Trends

-

Pillow-Type Machines:

- Smart upgrades: Integration of AI vision systems for defect detection.

- Multi-channel sealing to boost throughput.

-

L-Type Machines:

- Modular designs: Quick-change molds for flexible production.

- Seamless integration with robotic palletizing systems.

Conclusion

The fundamental distinction between pillow-type and L-type shrink wrapping machines lies in packaging design and scenario suitability:

- Pillow-type excels in fully sealed, high-integrity packaging for standardized small items.

- L-type dominates in stabilizing large or bundled goods with semi-open designs.

Enterprises should evaluate product specifications, production scale, and cost efficiency when selecting equipment. Hybrid production lines combining both technologies may offer optimal flexibility and productivity.