Four-Side Sealing Packaging Machine: A Modern Packaging Solution Combining Efficiency and Precision

In fast-paced industrial production, innovation in packaging machinery remains a core driver for enhancing efficiency and product quality. The four-side sealing packaging machine, as an advanced automated device, has become a “packaging guardian” in industries such as food, pharmaceuticals, daily chemicals, and electronics, thanks to its unique sealing technology and versatile applications.

1. What is a Four-Side Sealing Packaging Machine?

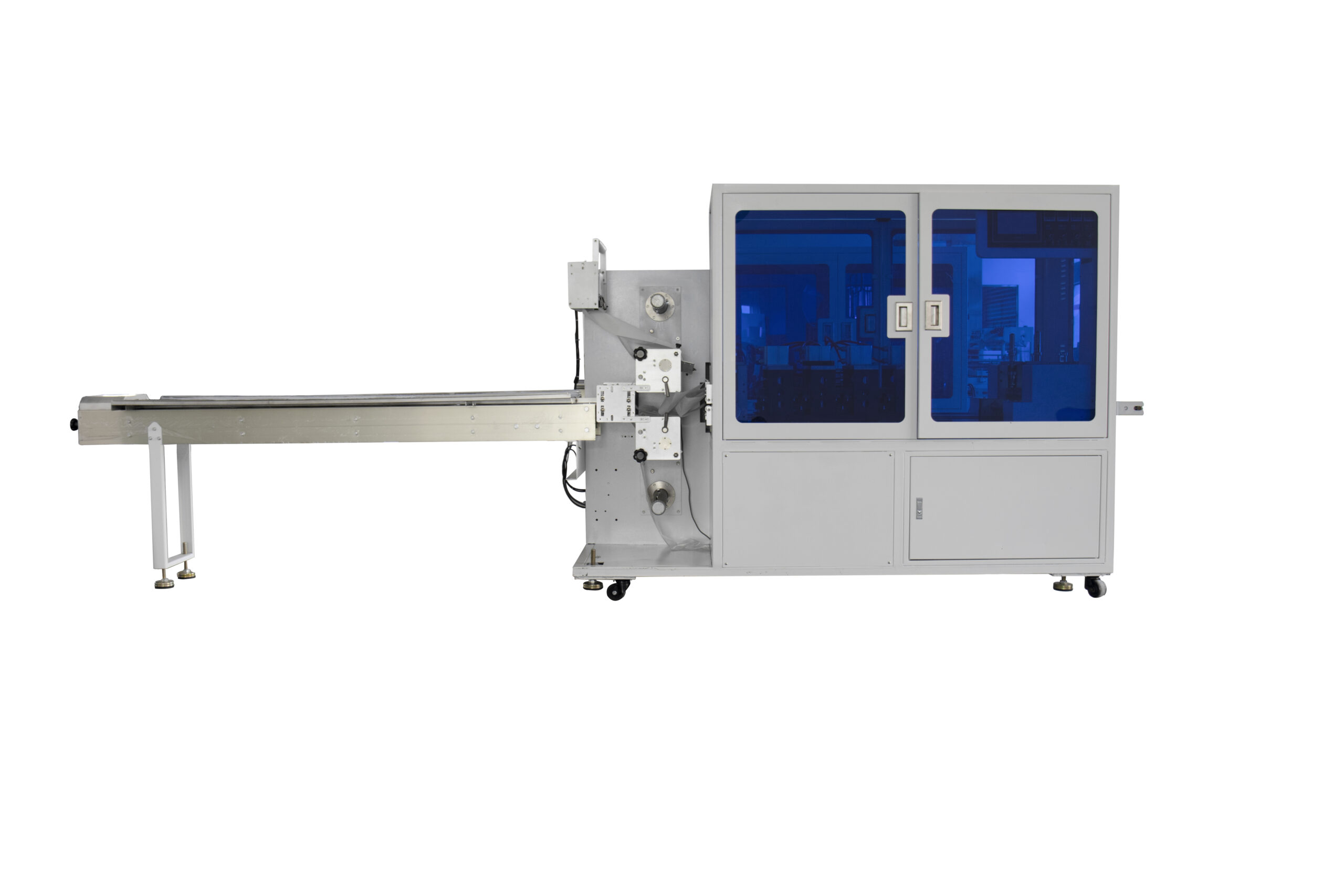

A four-side sealing packaging machine, also known as a “four-edge sealer,” is a device capable of simultaneously heat-sealing all four edges of a packaging bag. Unlike traditional three-side sealing machines, this technology uses two independent sets of heat-sealing molds (upper and lower) to seal the front, back, left, and right edges in one step after material filling, creating a uniform rectangular or square package. This process not only enhances aesthetic appeal but also significantly improves sealing performance.

2. Core Technology and Working Principles

-

Structural Design

The machine typically consists of a film feeding mechanism, bag-forming module, material filling system, heat-sealing unit, and cutting unit. Its core innovation lies in the heat-sealing mechanism: upper and lower molds, driven by pneumatic or servo systems, align precisely and apply high-temperature pressure to fuse all four edges of the packaging material rapidly. -

Workflow

- Film Feeding: Roll-based materials (e.g., PE, PET, or aluminum foil) are guided into the bag-forming zone via rollers.

- Bag Formation and Filling: The film is folded into a three-dimensional pouch, followed by precise filling of materials (granules, powders, liquids, etc.) through a dosing system.

- Four-Side Heat Sealing: Upper and lower molds close simultaneously to heat-seal all edges under controlled pressure.

- Cutting and Output: Packages are cut into individual units, completing the process.

-

Intelligent Control

Modern machines integrate PLC control systems and touchscreen interfaces, allowing parameter customization (temperature, pressure, speed). Some models also incorporate vision inspection systems to monitor seal quality in real time and reject defective products.

3. Key Advantages: Why Choose Four-Side Sealing?

-

Superior Sealing Performance

The fully enclosed structure effectively blocks air, moisture, and contaminants, extending shelf life—ideal for moisture-sensitive or oxidation-prone products like coffee, pharmaceuticals, and precision electronics. -

High Efficiency

Sealing all four edges in a single operation enables speeds of 60–200 packs per minute, boosting productivity by over 30% compared to three-side sealing machines, making it suitable for large-scale continuous production. -

Enhanced Aesthetics

Symmetrical, square-shaped packages elevate brand appeal. Customizable features like tear-notches, vent holes, or QR code areas further enhance functionality. -

Material Versatility

Compatible with various composite films, the machine meets diverse barrier requirements—for example, high-barrier films for sterilized medical products or breathable films for fresh agricultural goods.

4. Applications: From Food to High-Tech Industries

-

Food Industry

- Snacks: Moisture-proof packaging for chips and nuts.

- Beverages: Single-serve packaging for instant coffee and powdered milk.

- Frozen Foods: Leak-proof sealing for cold-chain logistics.

-

Pharmaceuticals and Cosmetics

- Medicines: Contamination-resistant packaging for granules or herbal extracts.

- Skincare: Single-use pouches for masks and serums.

-

Industrial Sector

- Electronics: Anti-static packaging for sensitive components.

- Hardware: Rust-proof sealed bags for screws and nails.

5. Market Trends and Future Prospects

-

Automation and Smart Integration

Aligned with Industry 4.0, four-side sealers now integrate robotics and IoT for remote monitoring, self-diagnosis, and flexible production lines. -

Sustainability-Driven Innovation

Demand for biodegradable materials (e.g., PLA films) challenges traditional heat-sealing techniques, pushing the development of low-temperature sealing processes to reduce carbon footprints. -

Compact and Modular Designs

To serve small and medium enterprises, compact models with interchangeable molds are trending, lowering initial investment costs. -

Global Market Growth

Industry reports indicate the global four-side sealing packaging machine market exceeded $1.5 billion in 2023, with the Asia-Pacific region leading growth due to expanding food and pharmaceutical production.

The four-side sealing packaging machine has redefined packaging standards through technological innovation, embedding efficiency, safety, and sustainability into production processes. As new materials and techniques emerge, this equipment will continue to drive the packaging industry toward smarter, greener solutions. Whether in traditional manufacturing or cutting-edge sectors, four-side sealing technology safeguards product value, solidifying its role as an indispensable “hidden champion” of modern industry.