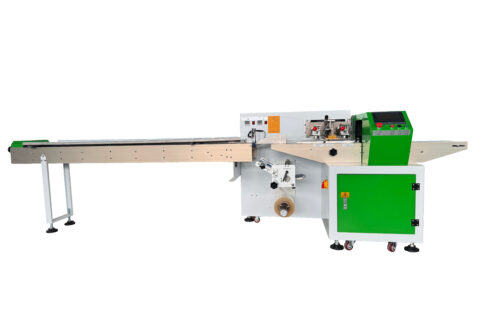

Packaging machine: the key tool to improve production efficiency and product quality

In modern industrial production, packaging machine, as an important equipment, plays an indispensable role. It not only improves production efficiency, but also improves product quality and market competitiveness. This article will explore in detail the various benefits of packaging machines, revealing their key role in the production and consumption process.

The packaging machine significantly improves production efficiency. Traditional packaging methods often rely on manual operation, which is not only time-consuming, but also prone to unstable packaging quality. Packaging machine through automatic operation, greatly shorten the production cycle. Modern packaging machines can complete a large number of packaging tasks in a short time, so that the overall efficiency of the production line is improved. In the food industry, for example, automated packaging machines can process hundreds of packages per minute, far faster than manual operation. This efficient production method allows enterprises to meet large-scale market demand while reducing labor costs.

Packaging machines also play an important role in improving product quality. The quality of packaging directly affects the safety and market acceptance of products. Through the precise control system, the packaging machine can ensure that each package meets the standard, avoiding the quality problems caused by uneven manual operation. In addition, the advanced packaging machine is equipped with a detection system, which can monitor the various indicators in the packaging process in real time, such as the tightness of the seal, the accuracy of the label, etc., to discover and correct potential defects in time, so as to ensure the quality of the product.

Packaging machines also play an important role in protecting products. During transportation and storage, products are vulnerable to external environmental impacts such as moisture, dust, and physical shocks. Packaging machines provide an effective protective layer for products through the use of various materials and technologies, such as airtight packaging, vacuum packaging, etc. This can not only extend the shelf life of the product, but also reduce the economic loss caused by damage during transportation. For example, packaging machines in the pharmaceutical and cosmetic industries, through special packaging technology, are able to ensure that products are not affected by external factors during long periods of storage and transportation, thus maintaining their effectiveness and safety.

Packaging machines also have significant advantages in improving the competitiveness of enterprises. With the intensification of market competition, consumers have higher and higher requirements for product packaging. Packaging machines can help companies achieve innovative packaging designs, such as unique packaging shapes and printing patterns, to attract the attention of consumers. By enhancing the visual effect and practicality of the packaging, enterprises can enhance the market recognition of the brand and the purchase desire of consumers. In addition, the packaging machine can also achieve personalized packaging needs, such as customized packaging size and label content, so as to meet the needs of different markets and consumers, and further enhance the market competitiveness of enterprises.

The intelligent and automated functions of the packaging machine also make the operation more convenient. Modern packaging machines are equipped with advanced control systems and human-machine interfaces that make it easy for operators to set and adjust various parameters. Through the automated operation process, the occurrence of human error is reduced and the overall operation safety is improved. At the same time, the intelligent packaging machine can automatically adjust the packaging speed and mode according to the production demand, so as to achieve flexible production scheduling. This intelligent feature not only improves production efficiency, but also reduces the dependence on professional operators, enabling enterprises to save human resources to a greater extent.

Packaging machines also have certain advantages in environmental protection. Modern packaging machines pay more and more attention to environmental factors in the design and production process. Many packaging machines use recyclable packaging materials, reducing the burden on the environment. At the same time, the packaging machine can effectively reduce the waste of materials in the packaging process, and maximize the use of every inch of packaging materials through the accurate measurement and control system. This environmentally friendly packaging not only meets the requirements of modern society for sustainable development, but also helps enterprises to enhance their social image and brand value.

In summary, packaging machines play an important role in improving production efficiency, ensuring product quality, protecting products, enhancing enterprise competitiveness, providing intelligent operation and environmental protection. It is not only an indispensable equipment for modern industrial production, but also an important tool to promote enterprise development and market competition. In the future, with the continuous progress of technology and changes in market demand, the functions and applications of packaging machines will be more diversified, bringing more convenience and benefits to all walks of life.