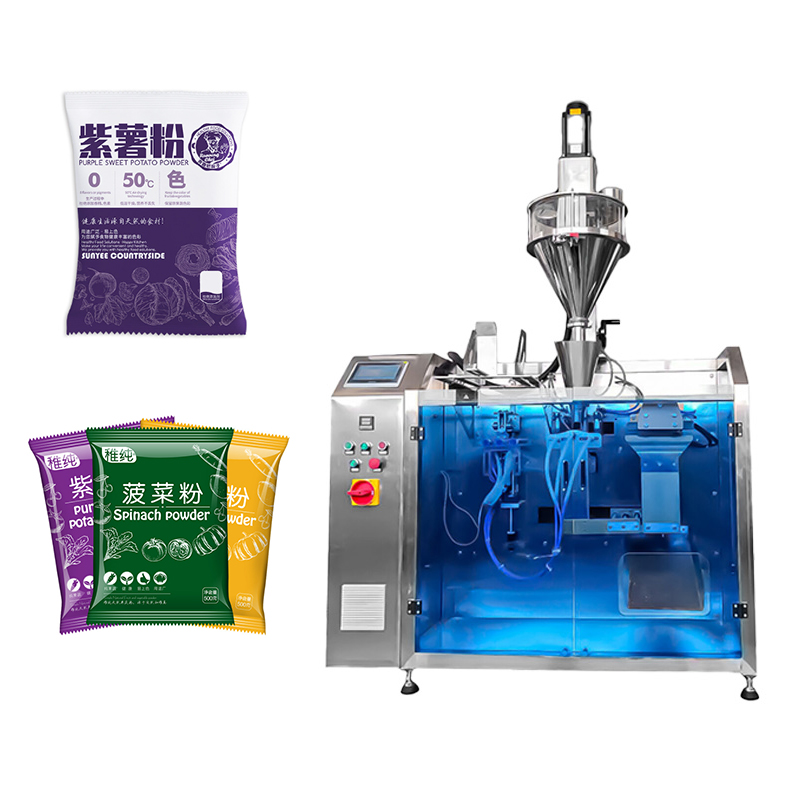

Fruit and vegetable powder bag packaging machine

The vegetable and fruit powder pre-made bag packaging machine stands as a cornerstone of modern food processing, combining intelligent control systems, pinpoint accuracy, and modular flexibility. By boosting packaging efficiency by over 30% and minimizing material waste, it significantly optimizes production costs. Suitable for both small-scale manufacturers and large industrial facilities, this machine enables standardized, scalable production of high-quality health-focused products. Its ability to meet growing global demand for nutritious, shelf-stable powders makes it an indispensable solution for upgrading packaging processes in the health food and related industries.

Description

1. Exterior Design

The vegetable and fruit powder pre-made bag packaging machine adopts a modular design, featuring a high-strength stainless steel body combined with food-grade protective coverings and transparent inspection windows, ensuring durability and compliance with hygiene standards. The compact structure minimizes floor space, and its corrosion-resistant surface treatment makes it suitable for humid or high-cleanliness workshop environments. Equipped with a user-friendly HD touchscreen interface for intuitive parameter adjustments, the machine integrates an automatic bag-feeding system at the top. Its streamlined appearance aligns with industrial aesthetics and modern production requirements.

2. Key Technical Specifications

- Packaging Speed: 40–80 bags/minute (adjustable based on bag type and powder flowability)

- Weight Accuracy: ±0.5%–1%, supported by multi-level electronic weighing

- Compatible Bag Types: Stand-up pouches, three-side-seal bags, four-side-seal bags, etc. (bag width: 50–200 mm; length: 60–300 mm)

- Power/Air Supply: 380V/220V 50Hz; air pressure: 0.6–0.8 MPa

- Dimensions: 1800 × 1200 × 2000 mm (L × W × H)

- Weight: Approx. 850 kg

3. Workflow

- Automatic Bag Feeding: Vacuum suction cups precisely grab pre-made bags, while robotic arms open and position them for filling.

- Precision Filling: A screw conveyor system, paired with high-sensitivity sensors, ensures accurate dispensing of powders with minimal dust generation.

- Vacuum Sealing: Multi-stage heat-sealing units perform degassing and sealing, with optional nitrogen flushing to extend shelf life.

- Product Output: Finished packages are transferred via conveyor to the collection area, with defective units automatically rejected.

- Quality Control: Integrated weight-checking and metal detection modules guarantee consistent net weight and product safety.

4. Core Advantages

- High Automation Efficiency: Fully automated operation reduces labor costs by over 60%.

- Precision Control: Servo-driven mechanisms and PLC programming achieve 30% lower error rates than industry standards.

- Multi-Scenario Adaptability: Interchangeable molds accommodate diverse materials, including blended powders, granules, and freeze-dried products.

- Hygiene and Safety: IP65-rated protection and CIP (Clean-in-Place) systems meet HACCP certification requirements.

- Energy Efficiency: Hybrid pneumatic-electric technology cuts energy consumption by 25% compared to conventional models.

5. Applications

- Fruit/Vegetable Processing: Spinach powder, strawberry powder, mixed nutrient blends.

- Health Supplements Industry: Protein powders, dietary fibers, probiotic drink mixes.

- Seasoning Manufacturing: Spice blends, instant soup bases, composite seasonings.

- Pet Food: Functional additives, freeze-dried snack powders.

- Pharmaceuticals: Herbal micro-powders, granulated medicinal products.