Pharmaceutical-Grade Aseptic Packaging Machine: 100% Compliance + Zero Defects!

Does your pharmaceutical packaging face these challenges? >- ❌ Failing cleanliness standards, leading to rejected batches? > – ❌ Human errors causing inconsistent filling volumes? > – ❌ Equipment unable to meet dynamic FDA/EU GMP requirements? DK Aseptic Packaging Machine is engineered for pharma — end-to-end isolation process, zero human contact, zero […]

Struggling with Small Hardware Packaging? One Machine Fits All Sizes—Get Your Solution Now!

Afraid of product bumping? The packing machine help you Tired of packaging small hardware parts with multiple sizes? Low efficiency? High labor costs? Time-consuming machine adjustments? The DK Multi-Function Packaging Machine** is specially designed for screws, nuts, washers, and other small hardware—adapting to all sizes with […]

Candy Needs Perfect Packaging – Don’t Let Poor Packaging Ruin Your Sweet Business!

Have you ever faced these problems? -Customers complain that candies become soggy, soft, or even stick to the packaging? – Manual packaging is inefficient and can’t keep up with order demands? – Competitors’ candies look more refined and appealing, while yours appear cheap? Poor packaging is silently eating away at your profits and brand reputation! […]

“0.1ml Error Killing Your Best Seller? The 2025 Cosmetic Packaging Survival Guide

“A Chinese beauty brand faced viral mockery for 0.3mm lipstick tube wobble, while competitors using magnetic packaging machines secured Sephora deals—precision now dictates brand survival!” 1. Cosmetic Packaging’s 5 Deadly Sins Self-Check: Is Your Brand Bleeding? [ ] Packaging flaws roasted on Xiaohongshu? [ ] Missed sales […]

Packaging machine: “Eco Scam? Labor Costs Soaring! The 2025 Survival Guide for Packaging Plants”

<“A Guangdong food factory was forced to reject million-dollar orders after its packaging workers mass-migrated to food delivery platforms—while competitors using fully automated lines undercut them by 25%… This isn’t an isolated case, but the start of industry upheaval.”> 1.The Death Toll of Traditional Packaging Labor Cost Black Hole: 30%+ monthly wage […]

E-commerce outbreak era: how to deal with the daily average of 100,000 orders with high-speed packaging machines?

When Orders Explode, Is Your Packaging Line a “Profit Engine” or a “Bottleneck”? 3 AM in an e-commerce warehouse: Workers scramble as overdue orders pile up on conveyors, while negative reviews flood in—’damaged packaging,’ ‘slow shipping’… Flexport research shows 72% of e-commerce customers abandon repeat purchases due to packaging inefficiencies. Manual packaging […]

Packaging Machine Usage Guidelines: 7 Key Points for Safe and Efficient Operation

Packaging machines are critical equipment in modern production lines, widely used in food, pharmaceutical, daily chemicals, and other industries. Standardized operation and scientific maintenance not only enhance efficiency but also prevent safety incidents and equipment wear. Below are seven essential precautions to ensure stable operation of packaging machines: 1. Pre-Operation Preparations Equipment Inspection Verify intact […]

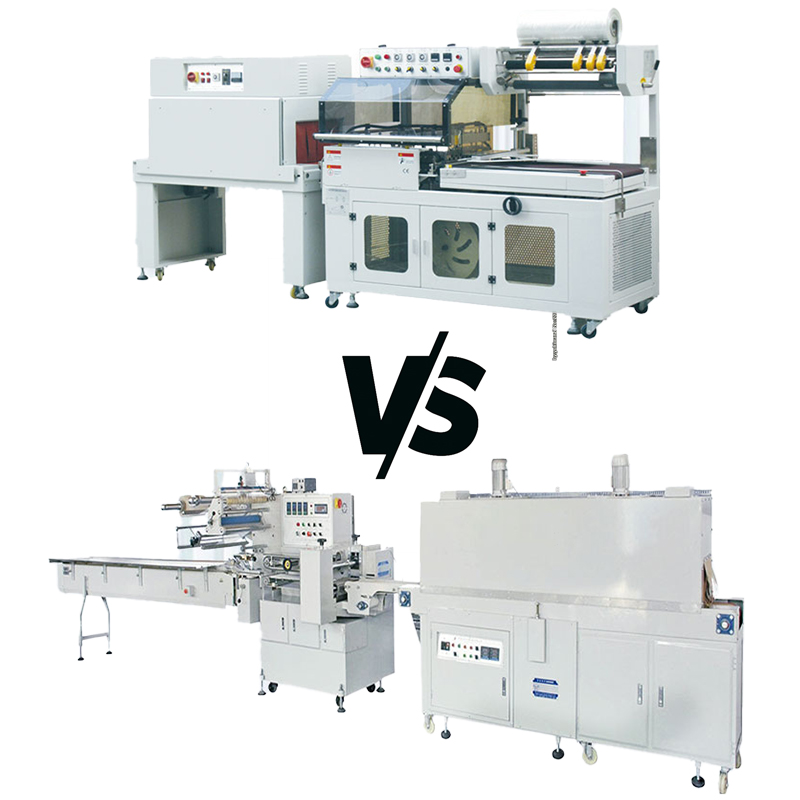

Analysis of Differences Between Pillow-Type and L-Type Shrink Wrapping Machines

In the industrial packaging sector, shrink wrapping machines are widely used for their efficiency, aesthetic appeal, and adaptability. Among them, pillow-type shrink wrapping machines and L-type shrink wrapping machines are two mainstream models, but they differ significantly in structure, functionality, and application scenarios. This article provides a multidimensional comparison to guide enterprises in selecting the […]

Multihead Weigher Packaging Machines: The Precision Weighing Revolution in Modern Industry

In a nut packaging workshop, 50 multihead weighers operate at a speed of 100 bags per minute, yet achieve dynamic weighing accuracy within ±0.5 grams. Behind this seemingly simple number lies a major breakthrough in industrial automation. As a core technology in intelligent packaging, multihead weigher packaging machines are reshaping global packaging standards across industries […]

Fully Automatic Screw Packaging Machine: An Efficiency Revolution in the Industrial Automation Era

In today’s rapidly advancing manufacturing sector, screws—as fundamental fasteners—are widely used in electronics, automotive, machinery, furniture, and many other industries. However, traditional manual or semi-automatic screw packaging methods, plagued by inefficiency, high costs, and human errors, have become a bottleneck hindering large-scale production. The emergence of fully automatic screw packaging machines not only addresses these […]