The Evolution and Impact of Packaging Machines in Modern Industry

Packaging machines have revolutionized manufacturing and logistics, enabling efficient, consistent, and cost-effective product handling. From food and pharmaceuticals to electronics and consumer goods, these machines play a vital role in safeguarding product integrity and enhancing brand value. This article explores their types, functions, and future trends.

Types of Packaging Machines

Packaging machines are categorized by their specific applications:

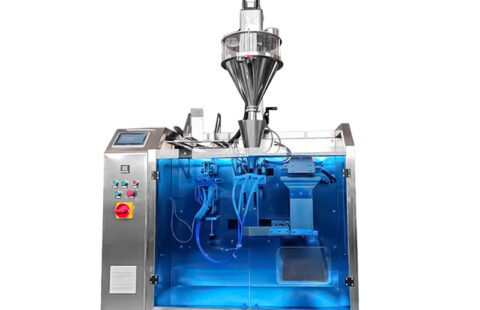

- Filling Machines: Dispense precise quantities of liquids, powders, or solids into containers. Common in food, beverage, and pharmaceutical industries.

- Sealing Machines: Secure packages using heat, adhesives, or pressure. Examples include bottle cappers and vacuum sealers.

- Labeling Machines: Apply labels with product details, barcodes, or branding. Critical for compliance and marketing.

- Wrapping Machines: Encase products in materials like film, foil, or paper. Used for candies, cosmetics, and perishables.

- Case Packers: Automate the loading of products into boxes or cartons, optimizing warehouse operations.

How Packaging Machines Work

Modern packaging systems integrate mechanical, electrical, and software components. A typical workflow involves:

- Product Feeding: Items are conveyed into the machine via belts, vibratory feeders, or robotic arms.

- Material Handling: Packaging materials (e.g., film, labels) are loaded and aligned.

- Form-Fill-Seal (FFS): Machines form packages, fill them, and seal them in one cycle. Ideal for snacks and medical supplies.

- Quality Checks: Sensors detect defects, ensuring proper sealing, labeling, and weight compliance.

- Output Sorting: Finished packages are sorted for storage or shipment.

Automation reduces human error, speeds up processes, and maintains hygiene standards—especially crucial in food and drug production.

Key Applications Across Industries

- Food & Beverage: Machines package items like chips, frozen meals, and bottled drinks. Modified atmosphere packaging (MAP) extends shelf life.

- Pharmaceuticals: Blister packs, syringe fillers, and tamper-evident seals ensure safety and dosage accuracy.

- Cosmetics: High-speed fillers and elegant wrapping enhance product appeal.

- E-commerce: Automated box-sizing machines reduce material waste and shipping costs.

Advantages of Automated Packaging

- Speed: Machines process thousands of units per hour, surpassing manual labor.

- Consistency: Uniform packaging minimizes rejects and maintains brand reputation.

- Cost Savings: Reduced labor expenses and material waste improve profitability.

- Safety: Minimizes human contact with hazardous or sterile products.

- Sustainability: Advanced machines optimize material usage, supporting eco-friendly goals.

Challenges and Innovations

Despite their benefits, packaging machines face challenges:

- High Initial Costs: Small businesses may struggle with upfront investments.

- Maintenance: Regular servicing is needed to prevent downtime.

- Flexibility: Retrofitting machines for new products can be complex.

Recent innovations address these issues:

- Smart Sensors: IoT-enabled devices monitor performance and predict maintenance needs.

- Modular Designs: Interchangeable components allow quick adaptation to different products.

- AI Integration: Machine learning algorithms optimize material usage and reduce errors.

Future Trends in Packaging Automation

- Sustainability: Biodegradable materials and energy-efficient machines will dominate.

- Personalization: Digital printing enables small-batch, customized packaging.

- Collaborative Robots (Cobots): Compact robots will work alongside humans in flexible setups.

- Blockchain Tracking: Secure data sharing will enhance supply chain transparency.

Packaging machines are indispensable in today’s fast-paced, quality-driven markets. As technology evolves, they will become smarter, greener, and more adaptable, driving efficiency across industries. Businesses investing in these innovations will gain a competitive edge while meeting consumer demands for safety, sustainability, and convenience.